Insights Don’t Drive Change. Action Does.

Executive Brick Manufacture Webinar | 25 Sept | 16:00 BST

Unlock process optimisation – measurable results in days

Featuring real outcomes from a major UK brick manufacturer.

Unlocking Performance

Harnessing Data to Transform Energy-Intensive Operations

In an era where the pace of change and technological advancement is faster than ever, industrial leaders have a unique opportunity to optimise performance and efficiency in their operations.

But where do you start, how do you make sense of your data, bring it all together from complex systems, and prove value quickly?

The answer lies in using your data, combined with your operational expertise, to deliver improved outcomes.

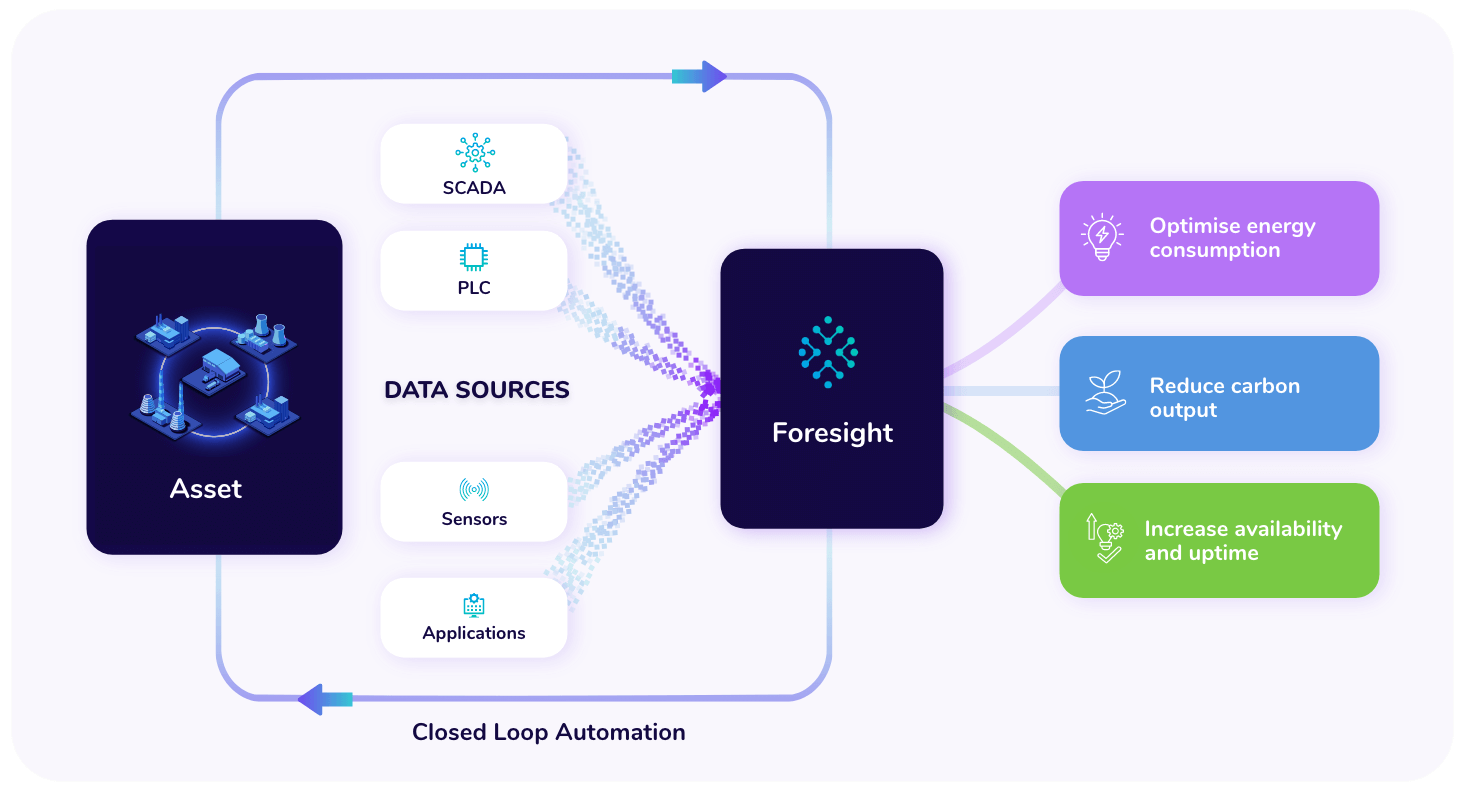

Meet ForesightTM

Your Optimisation Tool for Industrial Efficiency

Foresight is QiO’s fully autonomous AI-powered technology, giving industrial leaders the insights and tools to tackle their most pressing challenges.

Proven in the world’s leading energy-intensive industries, Foresight connects directly to your asset’s control systems, sensors, and other applications, capturing raw data and transforming it into a precise fingerprint of your processes.

Zero-touch automation makes hundreds — thousands — of micro closed-loop adjustments, optimising your assets processes for peak performance.

Executive Webinar for Process Manufacturers

23 Oct | 16:00 BST

How Manufacturers Cut Energy Waste in Days

Learn how to quickly optimise your equipment’s energy use.

Deploy As You Need it:

Deploy as you need it: on premises or in the cloud. Whether you want it to run in the background and silently optimise your operations, or surface critical insights in easy-to-read dashboards, you can.

Immediate Gains

Without Disruption

Quick Time to Value

Start seeing results straight away.

Risk-Free and Effortless

Plugs straight in to your existing processes.

Zero-Touch Optimisation

Runs in the background to reduce energy use.

Small reductions in kiln nature gas use by controlling temperature overshoots can lead to significant energy savings.

Most plants are sitting on savings hidden in data that's never been fully tapped, and around 10% of their burner energy use can be mitigated by Foresight.

How Foresight Helps

Kiln control optimisation

Continuously adjusts firing profiles and airflow based on live sensor data, reducing fuel waste and temperature overshoot.

Predictive monitoring

Identifies trends in kiln behaviour that could indicate faults or process drift, helping prevent downtime.

Data transparency and reporting

Clear, real-time dashboards for energy, cost, and emissions, giving teams and managers full visibility and actionable insights.

.gif)

Integrates with existing plant

More consistent brick quality

Lower gas or electricity consumption

You can’t afford instability in a furnace running 24/7.

Every fluctuation risks quality, and every inefficiency adds up fast. In a sector where energy is often the biggest cost line, precision and foresight make all the difference.

How Foresight Helps

Furnace control optimisation

Maintains stable melt temperatures and fine-tunes burner or electric input based on real-time data.

Predictive monitoring

Identifies trends in furnace behaviour that could indicate faults or process drift, helping prevent downtime.

Data transparency and reporting

Clear, real-time dashboards for energy, cost, and emissions, giving teams and managers full visibility and actionable insights.

Lower gas or electricity consumption.

More consistent glass quality.

.gif)

Integrates with existing plant control systems.

Melting, casting, reheating, and annealing all require heavy thermal input.

Overheating wastes energy, undershooting costs quality, and running idle eats margins. These can all be mitigated by Foresight’s real-time burner optimisation, based on live conditions in the furnace.

How Foresight Helps

Furnace control optimisation

Maintains stable melt temperatures and fine-tunes burner or electric input based on real-time data.

Predictive monitoring

Identifies trends in furnace behaviour that could indicate faults or process drift, helping prevent downtime.

Data transparency and reporting

Clear, real-time dashboards for energy, cost, and emissions, giving teams and managers full visibility and actionable insights.

Lower running costs and less wasted heat.

More reliable production with fewer unplanned stops.

Data easily accessed by plant teams.

Foresight’s real-time optimisation mitigates this by adjusting burner temperature based on live conditions in the kiln.

Tunnel kilns and dryers are complex systems; when they’re not running efficiently, you risk wasting both energy and product, as inconsistent firing can lead to cracks, warping, and waste.

How Foresight Helps

Kiln control optimisation

Continuously adjusts firing profiles and airflow based on live sensor data, reducing fuel waste and temperature overshoot.

Dryer monitoring

Tracks temperature and humidity to prevent over- or under-drying.

Data transparency and reporting

Clear, real-time dashboards for energy, cost, and emissions, giving teams and managers full visibility and actionable insights.

Reduced fuel and electricity use.

Improved product yield with fewer defects.

Operators remain fully in control.

Foresight’s real-time optimisation mitigates this by adjusting the temperature based on live conditions in the dryer.

Drying is your biggest energy load. If you rely on static settings and manual adjustments, you run the risk of over-drying product, resulting in uneven quality and steam going to waste.

How Foresight Helps

Dryer and steam system optimisation

Tracks temperature and humidity to prevent over- or under-drying. Detects temperature or pressure issues quickly.

Predictive monitoring

Identifies trends in equipment behaviour that could indicate faults or process drift, helping prevent downtime.

Data transparency and reporting

Clear, real-time dashboards for energy, cost, and emissions, giving teams and managers full visibility and actionable insights.

Significant energy savings, especially in drying.

More stable operation and sheet quality.

Plug-in deployment: no major changes needed.

Energy is a major overhead in food and beverage production especially across ovens, steamers, fryers, and chillers.

Whether you’re baking, roasting, or sterilising, even small temperature swings can throw off consistency and inflate your bills. Foresight’s real-time optimisation mitigates this by adjusting temperatures based on live conditions.

How Foresight Helps

Oven and line optimisation

Continuously monitors and tunes oven temperature, humidity, and airflow to match recipe and batch size, eliminating temperature swings and hotspots.

Product consistency

By holding oven temperature rock steady, Foresight helps ensure every batch meets spec with less reliance on constant operator intervention.

Data transparency and reporting

Clear, real-time dashboards for energy, cost, and emissions, giving teams and managers full visibility and actionable insights.

Lower gas and electricity costs across all major lines.

Improved and more consistent product quality.

Simple retrofit with no need to overhaul existing controls.

Proven Results

QiO helped a major UK brick manufacturer optimise kiln control across multiple manufacturing sites, reducing gas waste and carbon emissions in one of the UK’s most energy-intensive sectors.

By integrating with their existing PLCs, Foresight now makes thousands of real-time adjustments per day, stabilising temperatures, improving efficiency, and eliminating overshoot and waste.

ROI

Full ROI within weeks

10-11%

Reduction in energy use

12,000+

Tonnes of carbon saved annually (projected)

Let’s Put Your Data to Work

Whether you’re chasing emissions targets or cutting overheads, it starts with a single data point - yours.